Whether it’s new locations, new products, or accelerated growth in your existing locations, there are a handful of non-negotiables.

There will more likely be less of your personal presence but it will require more of your professional experience. Here’s what I mean –

If you’ve read a few of these posts, you know I’m a big believer in policies and processes. If you don’t already have well-documented, carefully-followed processes in place for your organization’s essential value creation activities, you’re not ready to scale. Every burger should look like the one on the digital menu board. Every widget should be manufactured exactly to specs with no variation in quality from widget to widget. Every invoice should account perfectly for every product or service sold and be delivered to the client on a consistent schedule. If your team doesn’t religiously follow a recipe to make these things happen, start there before you think about scaling. If you need help with that, check out this chapter from my book.

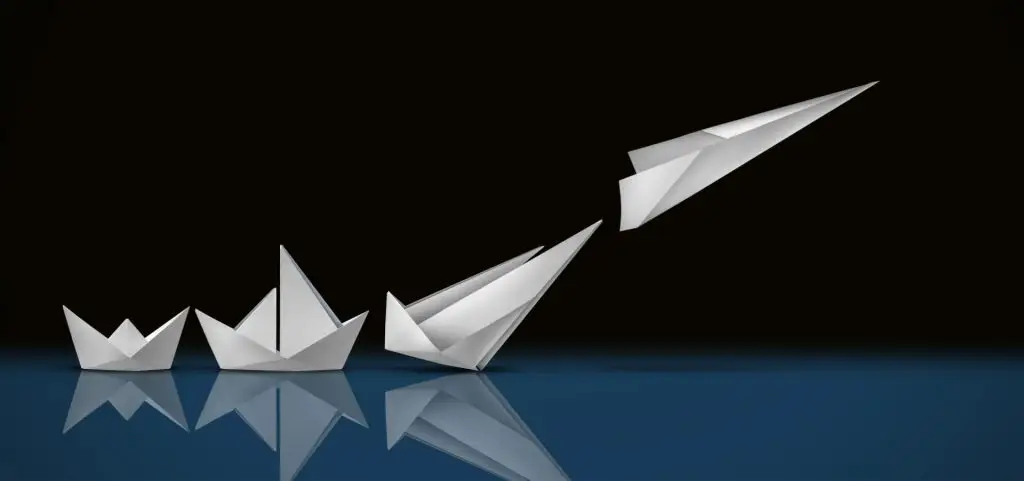

In this post, we’re assuming your organization is faithfully following processes and you’re ready to 2X, 5X, 10X, or 20X your business.

Elevate the Customer Experience – You know the drill – your favorite restaurant opens a new location closer to your house. You’re excited to get your favorite tacos, pizza, sushi, or wings with a much shorter drive. After one or two visits, you decide that, from now on, you’re going to drive back to the mothership because the closer location “just isn’t the same.” If you don’t want customers to do that as you scale your business, you’ve got to elevate the customer experience. Rich Karlgaard reminded us in The Soft Edge, that customers interact on three levels – function (the product does what it’s supposed to do), form (the product is beautiful or easy to use), and feeling (the experience confirms my buying decision so fully that I want to do it again and feel the same feeling). As you scale, each interaction with a new product, new location, or new delivery methodology must check all three boxes. Invite team members involved in the delivery of the new offering (product, location, etc.) into a story that challenges them to make the interactions surrounding the new offering as good or better than customer’s past interactions with the organization. This is where company culture informs the work of the team members involved in the scaled interaction. There can’t be any daylight between the mothership and the scaled offering.

Increase Team Member Expertise – As your physical presence decreases (if your scaling involves multiple locations, this will absolutely happen), every team member needs to be better equipped to do their job. Certainly the implementation of policies and processes is the first step, but their growth needs to go way beyond just that. If you want team members to make decisions like you make them, they need to understand what constitutes “winning” in the organization. Part of that might be having access to the same information you have. I’m not saying they need access to private financial information, but they need to understand the key performance indicators for the organization. During the French Revolution, the Germans introduced “Commander’s Intent” – a succinct description of what constitutes success for a specific military mission. Before the mission began, each soldier, irrespective of rank, was briefed on the Commander’s Intent for the mission. If a soldier’s immediate superior was killed during the mission or the soldier became separated from their unit, they understood the endgame and could make independent decisions accordingly. As you’re scaling, your team members need to understand your “Commander’s Intent.”

Understand Economies and Diseconomies of Scale – Economies of Scale has a much better marketing team than Diseconomies of Scale. Everyone understands the former, but much fewer understand the latter. We all understand that buying larger quantities of something lowers the price and that spreading the fixed cost of a piece of equipment over more units produced drives down the cost per unit. But that math only works to a point. As you scale, you have to become more adept at managing the break points. For instance, if you have a widget making machine that can produce 100,000 units per year, it’s all good as you grow up through 30, 50, and 70 thousand units, but as soon as your sales team sells widget 100,001, things change. If that sale means that another widget making machine must be purchased, your fixed costs formula radically changes – essentially doubling. The same type of math can be done with adding new supervisors or adding additional shifts. This is a very over-simplified example because there are multiple way to manage a situation like this (like using a contract manufacturer for the excess demand until you can make the math work for a second widget making machine). But you get the idea.

There are certainly more factors that come into play as you scale but these three will get you further down the road.